Hydraulic cylinders are integral components in a wide range of industries, from construction to manufacturing. These devices are used to generate linear force through the application of hydraulic fluid under pressure, and understanding how they work and what makes them efficient is key to choosing the right hydraulic system for your needs. In this article, we will delve into the definition, types, diagram, function, and working principles of hydraulic cylinders.

A hydraulic cylinder is a mechanical device that uses pressurized hydraulic fluid to create a linear motion. It consists of a cylinder barrel, a piston, and a piston rod. The piston divides the cylinder into two chambers, one that receives the fluid and one from which the fluid is expelled. Hydraulic cylinders are commonly used in machinery to create force or perform work like lifting, pushing, or pulling.

A hydraulic cylinder is a critical component in hydraulic systems, used to convert hydraulic energy into mechanical energy. Essentially, they provide linear motion, allowing machines to exert powerful forces. Hydraulic cylinders are primarily used for applications where heavy lifting or force generation is necessary, such as in construction equipment, agricultural machinery, and industrial presses.

Hydraulic cylinders are constructed from materials that can withstand high pressures and wear. Typically, the barrel is made from steel, providing strength and resistance to external damage. The piston and piston rod are often made of chrome-plated steel or stainless steel, offering durability and resistance to corrosion. The seals inside the cylinder are made from synthetic materials, designed to prevent leaks and maintain the hydraulic fluid's pressure and cleanliness.

The hydraulic cylinder speed is influenced by the flow rate of the hydraulic fluid, the size of the cylinder, and the load it is handling. Hydraulic cylinders can operate at varying speeds, but they typically offer controlled and smooth motion. The speed is adjustable by modifying the flow of hydraulic fluid into the cylinder, which can be managed using valves in the hydraulic system. For high-speed applications, such as in automation, an adjustable hydraulic cylinder can operate at very fast speeds with proper system setup.

https://youtu.be/-EiufxtGRao?si=DE-t6ORR1eiTAN3u

Author: EMecha3D

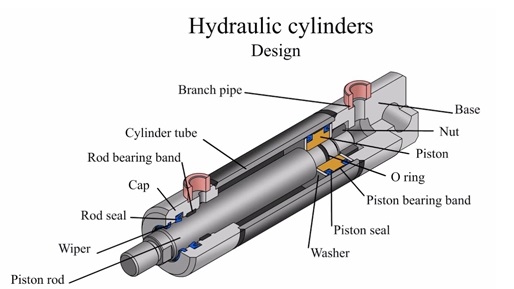

Understanding how a hydraulic cylinder works is easier when looking at its diagram. A basic schematic of a hydraulic cylinder includes the following components:

Piston: The internal component that moves back and forth within the cylinder barrel, dividing the cylinder into two chambers.

Piston Rod: Extends from the piston and is used to deliver force to external equipment.

Seals: Prevent fluid from leaking and maintain internal pressure.

End Caps: Caps that seal the ends of the barrel, providing support and allowing the cylinder to be mounted on machinery.

Wiper: The wiper is a sealing element located at the end of the cylinder that prevents dirt, debris, and contaminants from entering the cylinder and damaging the piston rod or seals.

Rod Seal: The rod seal ensures a tight seal between the piston rod and the cylinder barrel, preventing hydraulic fluid from leaking out and maintaining pressure within the cylinder.

O-Ring: O-rings are used in various parts of the hydraulic cylinder, such as between the piston and cylinder barrel or in the end caps. They help create a leak-proof seal by fitting tightly around the surfaces to block fluid from escaping.

Selecting the right type of hydraulic cylinder depends on the specific application. Several hydraulic cylinder types are available, each suited for different uses. Below are some of the most common types:

Welded hydraulic cylinders are designed for use in more rugged environments, such as construction and heavy-duty machinery. These welded cylinders feature a welded construction rather than being bolted together. The welded design makes them stronger and more resistant to external stresses. They are also more compact, making them ideal for applications where space is limited.

| Welded Hydraulic Cylinders Types | ||||

| ACL Adjustable Welded Clevis Hydraulic Cylinder | WBU Welded Hydraulic Cylinder Cross Tube | WCL Clevis Welded 3000 PSI Hydraulic Cylinder | WTH Pin Eye Hydraulic Cylinder | |

| Operating pressure | 3000PSI | 3000PSI | 3000PSI | 3000PSI |

| Construction | Heavy-duty welded construction | Heavy duty welded construction | Heavy duty welded construction | Heavy duty welded construction |

| Materials | Ductile iron material for Piston and Gland Honed steel tube and precision-finished | Ductile iron for Piston Hard chrome plated steel rod Honed steel tube, precision finished | Ductile iron for Piston Hard chrome plated steel rod Honed steel tube, precision finished | Ductile iron for Piston Hard chrome plated steel rod Honed steel tube, precision finished |

| Seals | All seals are manufactured to US specification | Hallite | Hallite | Hallite |

| Ports | SAE ports available | NPT, SAE, BSP available | NPT, SAE, BSP available | NPT, SAE, BSP available |

Tie rod cylinders are generally used in industrial and mobile applications. These cylinders are held together by external tie rods, which offer more flexibility in terms of design and assembly. They are often used when the cylinder needs to be disassembled or repaired regularly. Tie rod type hydraulic cylinder is widely used in manufacturing machinery, lifts, and vehicle lifts.

| Tie Rod Hydraulic Cylinders Types | ||

| 3000 PSI Tie Rod Cylinders | Tie Rod 2500 PSI Hydraulic Cylinders | |

| Operating pressure | 3000PSI | 2500PSI |

| Application | Medium duty | Light and medium duty |

| Materials | Ductile iron for Piston Hard chrome plated steel rod Honed steel tube, precision finished | Ductile iron for Piston Hard chrome plated steel rod Honed steel tube, precision finished |

| Seals | Top quality seals | Top quality seals |

| Ports | NPT, SAE, BSP available | NPT, SAE, BSP available |

Telescopic cylinders are used for applications that require extended reach with a compact form factor. They feature multiple nested stages, which allow the cylinder to extend to a much longer length than its initial size. Commonly used in dump trucks, material handling, and other vehicles requiring a long stroke, telescopic hydraulic cylinders are ideal for space-saving designs without compromising on performance.

| Telescopic Hydraulic Cylinders Types | ||

| Inverted Telescopic Cylinder Working | Custom Telescopic Hydraulic Cylinders | |

| Advantages | Small size and long stroke | Bore size up to 1000mm and stroke up to 15,000mm |

| Operating pressure | 7 Ton Series, 2000PSI Rated 12 Ton Series, 2300PSI Rated | Up to 5000psi |

| Stages | Two to six stages | Up to 7 stages |

These specialized cylinders are used in snowplows to control the lifting, angling, and lowering of the plow. The snowplow cylinder needs to operate in harsh winter conditions, built to endure extreme temperatures and heavy-duty operation. Hydraulic cylinders for snow plow are often designed to handle dynamic loads, such as when lifting or angling a snowplow in response to varying snow depths.

| Characteristics of Snowplow Cylinder | |

| Operating pressure | 3000PSI |

| Applications | Snow plowing |

| Materials | Ductile iron for Piston Hard chrome plated steel rod Honed steel tube, precision finished |

| Seals | Hallite |

| Ports | NPT, SAE, BSP available |

In some cases, off-the-shelf hydraulic cylinders may not meet the specific needs of an application. Custom hydraulic cylinders are tailored to meet exact specifications, whether it's in terms of size, pressure, stroke length, or special materials. Engineers design these hydro custom cylinders based on the application's unique requirements, ensuring optimal performance.

Hydraulic cylinders are used in applications where linear force and motion are required. Their main function is to move a load using hydraulic pressure. They are most commonly found in construction machinery, agricultural equipment, manufacturing lines, and automotive industries. Some typical uses include:

Excavators and Bulldozers: Hydraulic cylinders in these machines help lift and move heavy loads, such as earth and debris.

Presses and Injection Molding Machines: Hydraulic cylinders create the force needed for pressing and molding materials into desired shapes.

Elevators and Lifts: Hydraulic cylinders are employed to lift heavy loads vertically.

Agricultural Machinery: Tractors and harvesters rely on hydraulic cylinders for agriculture to lift, push, or pull various parts of the machinery.

The hydraulic cylinder working principle is based on Pascal's Law, which states that a change in pressure applied to an incompressible fluid is transmitted undiminished throughout the fluid. When hydraulic fluid is pumped into one side of the cylinder, the piston is forced to move. The pressure created by the hydraulic fluid generates a force on the piston, which in turn moves the piston rod to do work.

Here's how the process works:

Fluid is Pressurized: The hydraulic pump generates pressure by forcing fluid into the cylinder.

Pressure is applied to the Piston: As the fluid enters the cylinder, it applies pressure to the piston, which moves in a linear motion.

Piston Rod Moves: The piston rod extends or retracts, transferring the force to the connected load.

Return Stroke: When fluid is allowed to flow out of the cylinder, the piston returns to its original position, ready for another cycle.

The design of hydraulic cylinders allows them to produce significant force relative to their size, making them invaluable in heavy-duty applications. Additionally, the use of hydraulic fluid enables smooth and controlled motion, even under extreme conditions.

Hydraulic cylinders play a pivotal role in numerous industries by converting hydraulic energy into mechanical work. Understanding their definition, types, function, and working principle is essential for selecting the right cylinder for your needs. With various types available, such as welded, tie-rod, and telescopic cylinders, there is a hydraulic solution for nearly every application, whether it's lifting heavy loads, controlling machinery, or performing precision tasks. By exploring the hydraulic cylinder system China offerings, businesses can find reliable and efficient solutions tailored to their specific requirements.