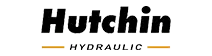

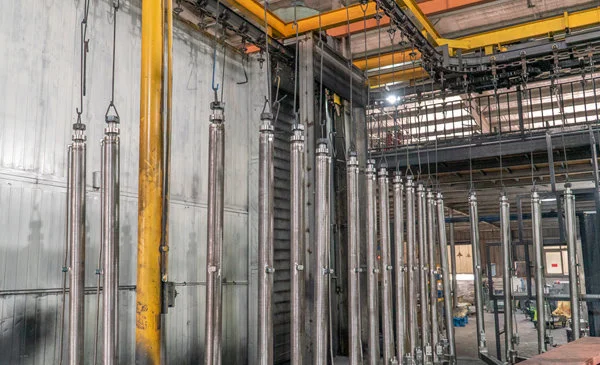

The Engineering team at Hutchin Hydraulic works with sales to develop custom cylinder solutions based on your specific requirements. Our products are engineered to withstand extreme work environments. Our experts are here to be an extension of your business.